Business

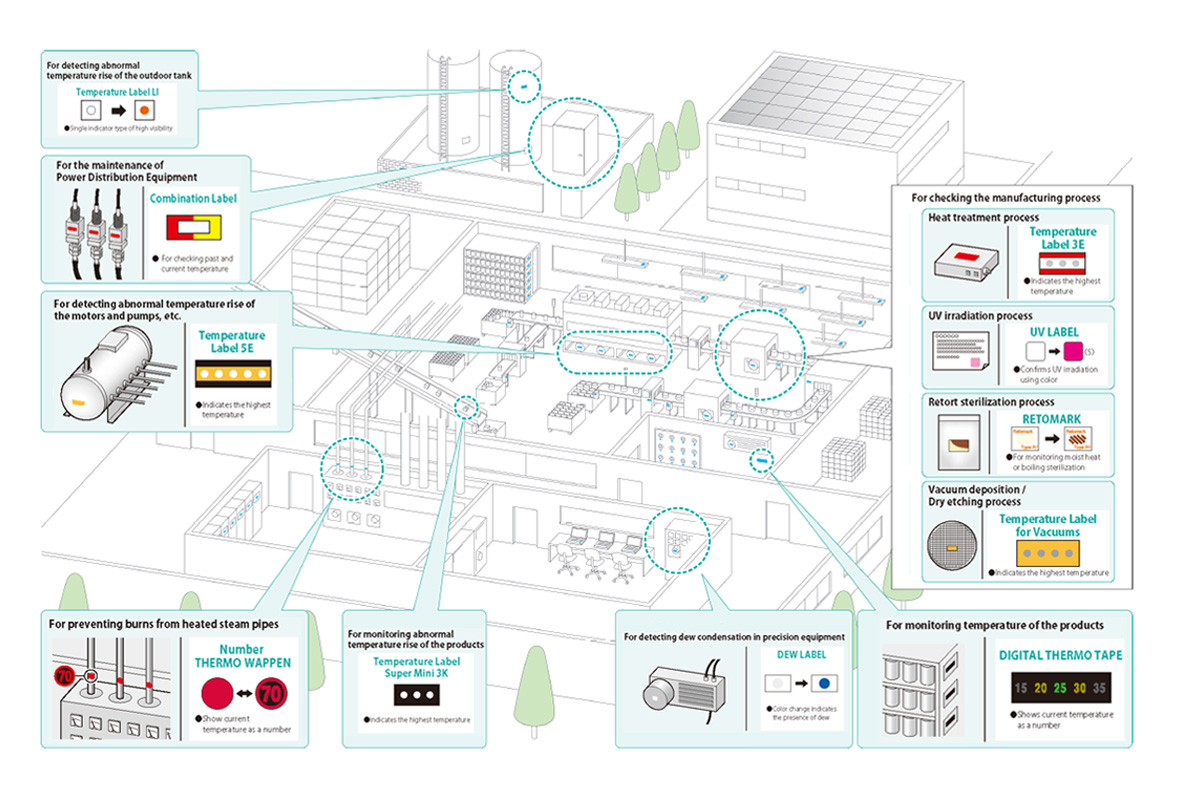

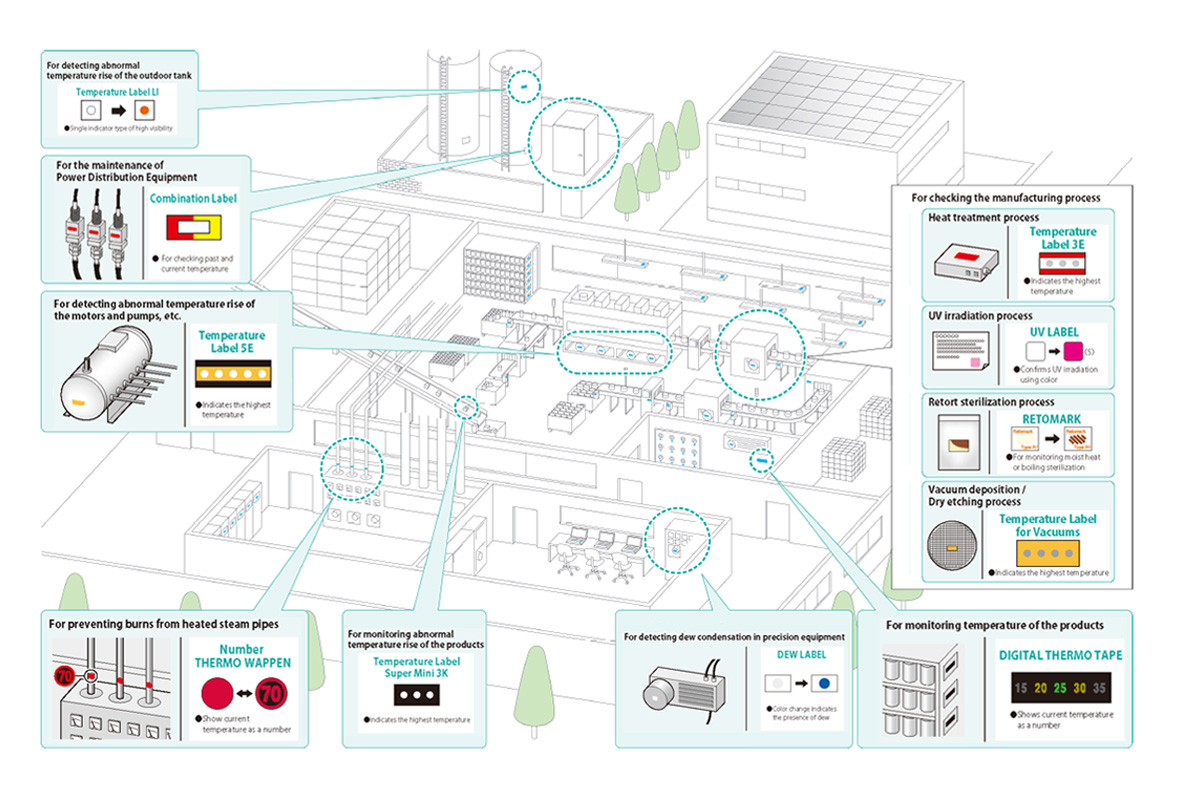

Example of use

- Factory-side

- power-side

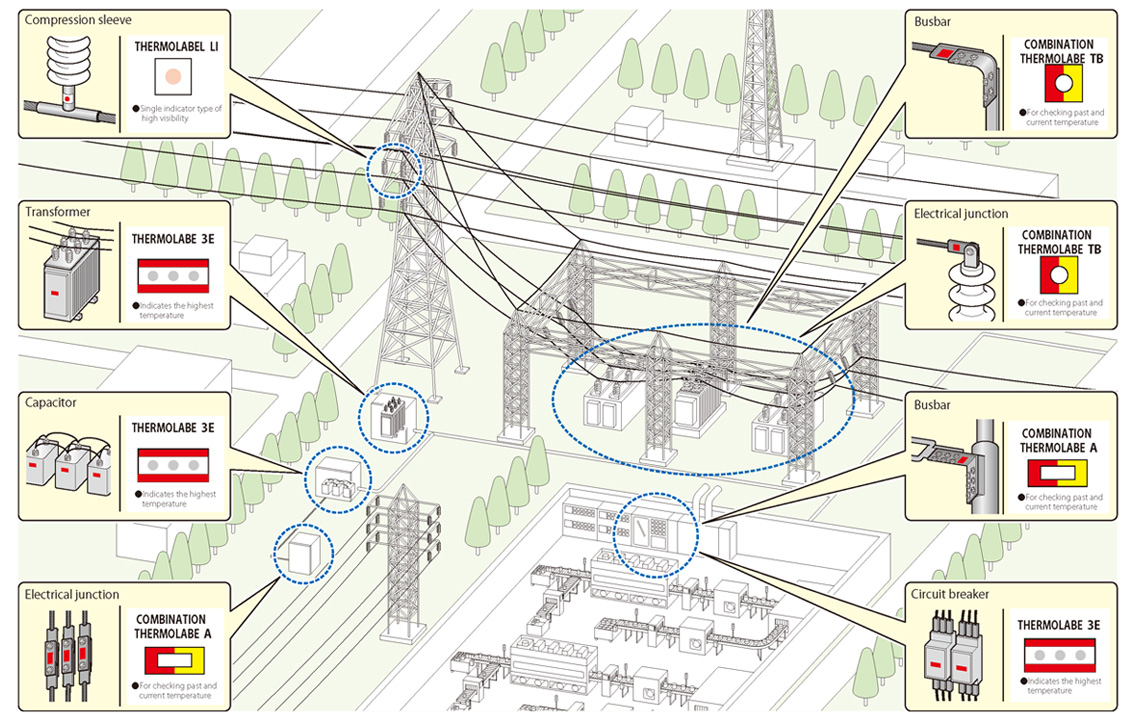

Temperature Indicating Materials – Usage Examples

For maintenance of electrical/electronic equipment

-

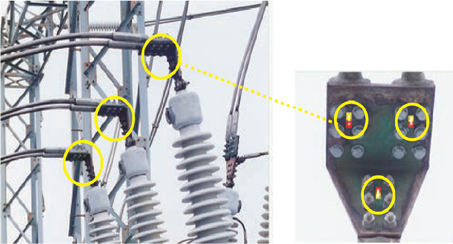

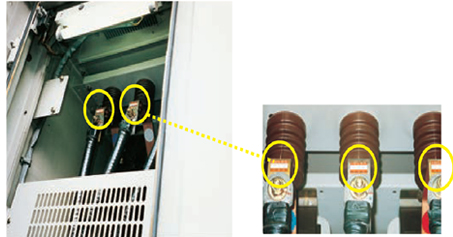

Power Transforming Equipment

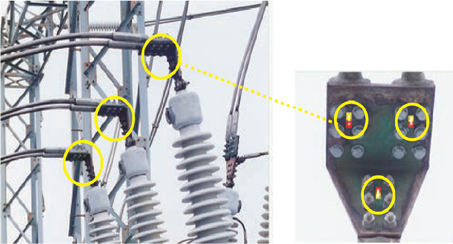

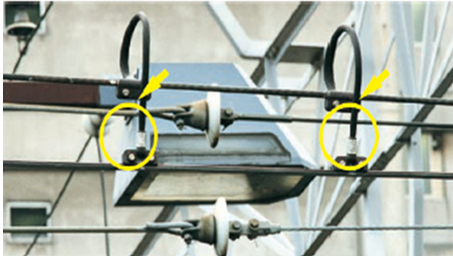

- Monitoring abnormal temperatures in electric power equipment and terminal connections

- Line switch (LS) fixed contact exterior

- Oil circuit breaker (OCB) terminal fastener

- Transformer (Tr) terminal fastener and main body

- Silicon capacitor (SC) terminal fastener

- Monitoring abnormal temperature in current transformer (CT) terminal fasteners and super high-voltage transformers

-

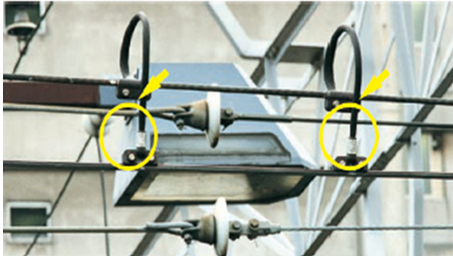

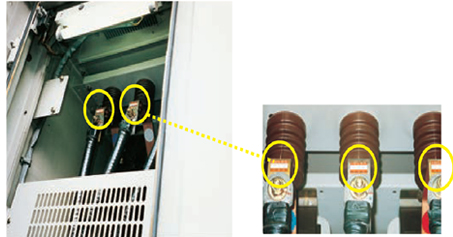

Power Distribution Equipment

- Monitoring abnormal temperatures in busbars, circuit breakers and MBB connections inside power-receiving cubicles

- Pole-mounted transformer load management

- Monitoring abnormal temperatures in power capacitors, arc suppression resistors and terminals and blade parts of circuit breakers

-

Control Equipment

- Temperature monitoring of electromagnetic switches, electromagnetic contactors, electromagnetic relays, knife switches, high-voltage circuit breakers, high-voltage load break switches, power capacitors (parallel, high-voltage, series), surge arresters, inductive reactors, and magnetic amplifiers

-

Rotating Electrical Equipment

- Temperature monitoring of motors, Temperature monitoring of rotating machine parts

- Stator windings/insulated rotor windings

- Armature windings with commutators

- Resistive field winding and compensating winding

- Exposed single-phase field winding

- Commutators and slip rings

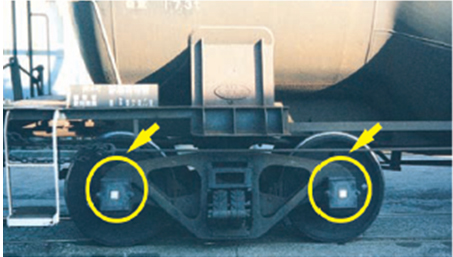

- Bearings

-

Electronic Components

- Circuit components: Temperature monitoring of capacitors, resistors, coils and integrated circuits

- Vibrating components: Temperature monitoring of crystal oscillators, mechanical filters and reed selectors

- Mechanical components: Temperature monitoring of electromagnetic relays, connectors, plugs, jacks and switches

- Semiconductor devices: Temperature monitoring of transistors, diodes, thyristors and integrated circuits

-

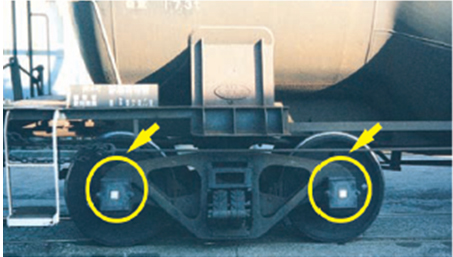

Power Transmission Equipment

- Monitoring for abnormal heat generation in jumper compression sockets and sleeves

- Temperature monitoring of terminals for feeder lines, negative feeder lines, overhead lines, support lines, feed branch connectors, jumper connectors, branch connectors, feed ears, connectors, and feeder switches

-

For monitoring household items

- Gas water heater water temperature sensing and burn prevention

- Temperature sensing for hot plates and frying pans

- Temperature sensing for hot sake bottles

- Monitoring/measurement of temperature inside refrigerators

- Room temperature monitoring/measurement

- Temperature sensing for electric moxibustion utensils

- Confirmation of body warmer ignition

- Temperature sensing for hair irons/hair curlers

- Temperature indication for vacuum cleaners with mite-removing function

-

For monitoring temperature in manufacturing processes

- 1. Mining

- Temperature monitoring of metal melting furnaces

- Determining completion of refining during electrorefining of copper

- Temperature monitoring for heat treatment

- Temperature monitoring of bucket conveyors

- 2. Automobiles/Shipbuilding

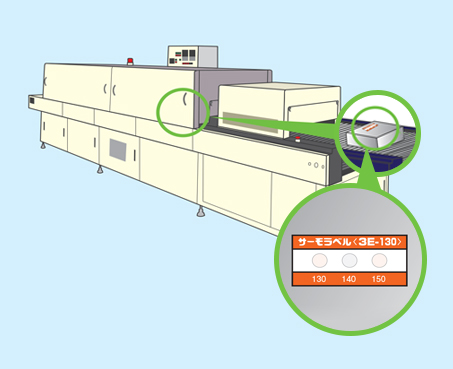

- Temperature monitoring during paint baking

- Confirmation of brake shoe adhesive hardening conditions

- Temperature monitoring of molds and dies

- Confirmation of engine internal temperature

- Confirmation of preheating temperature during welding

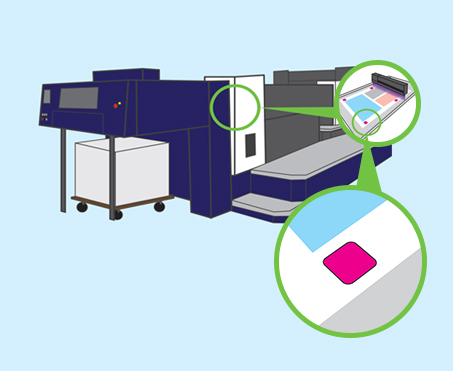

- 3. Electrical/Electronic/Communication Equipment

- Temperature monitoring during light bulb manufacturing

- Checking light bulb life

- Checking temperature increases inside electrical machinery

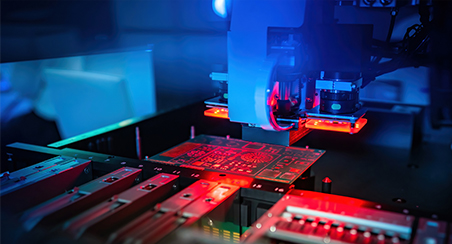

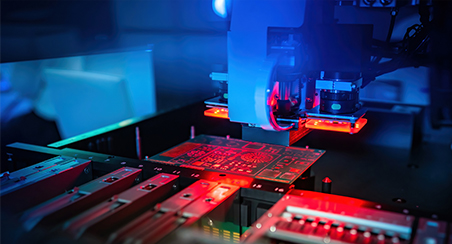

- Checking temperature increases of printed circuit boards

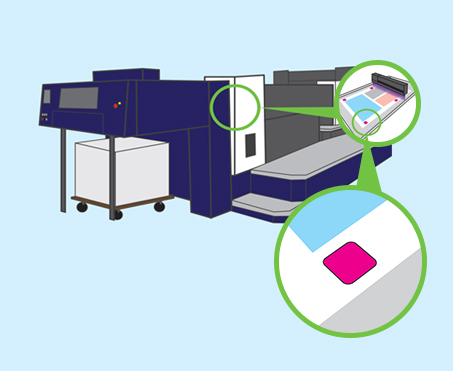

- Checking temperature in heat treatment for copiers

- Determination of heating factuality in response to complaints

- Temperature monitoring for heat treatment of heat-shrinkable tubes for communication cables

- 4. Food

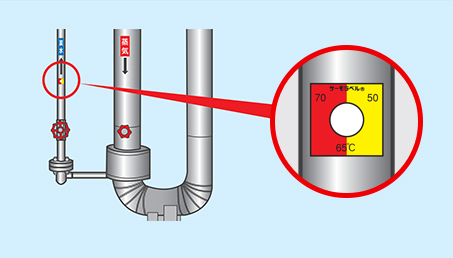

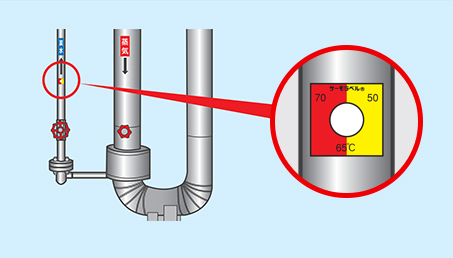

- Level gauges for brewing tanks

- Checking temperature In heat processing during manufacturing

- Checking temperature in heat processing of udon noodle heating

- Confirmation of temperature during breadmaking

- Checking temperature rise during transportation

- 5. Textiles

- Temperature monitoring during printing

- 6. Schools

- Checking the temperature of sterilizing cabinets for school lunch utensils

- Checking heat transfer for educational materials

-

Combination temperature label A

-

Customized temperature label LI

-

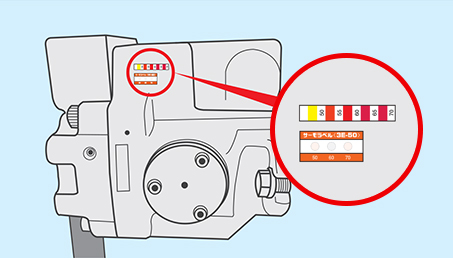

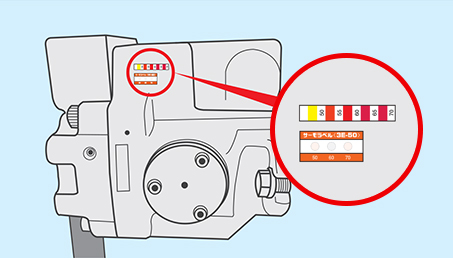

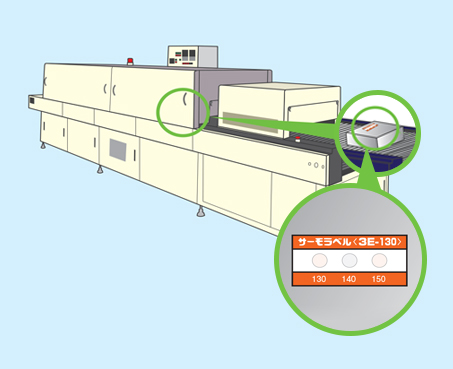

Temperature label 3E

-

temperature label LI

-

Thermo paint

-

Thermosheet C

Temperature lable 3E -

UV label S

-

Combination temperature label TB

-

Temperature lable 3E

-

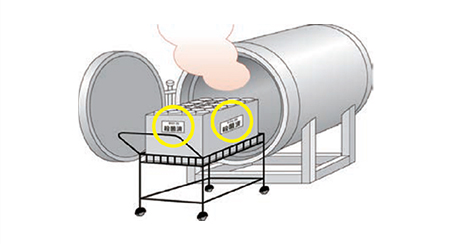

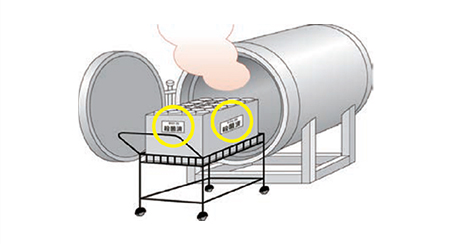

Sterilization process monitoring card

- Confirmation of processes for retort-packaged food/Checking completion of heating processes during canned food manufacturing

- Checking the temperature of utensil sterilizing cabinets for school lunches

- Confirmation of autoclave sterilization

-

Sterilization process monitoring card

- Temperature monitoring during transportation/storage of pharmaceuticals, chemicals and frozen food

- Temperature monitoring during low-temperature transportation

- Temperature monitoring inside warehouses

- Food freshness maintenance

- Checking temperature history during transportation of chocolate

- Checking the temperature inside refrigerators

-

FOR UV

- 1. Adhesion & curing

- For curing plates, such as camera modules, display panels, touch panels, etc.

- 2. Print

- Efficient drying hardening of ink such as paper surfaces, packages, sealabels, etc.

- 3. Painting & Coating

- Short construction time and excellent preservation performance for automotive parts, construction materials, and electronics

- 4. Washing, texture

- Effects of organic cladding, such as print substrate, condenser, silicon wafer, IC card, etc. or improve adhesion and adhesion. Utilize for high efficiency of processes

- 5. Sterilization

- It is used for accurate sterilization because there is little deterioration such as food, medicine, cleaning water, clean room, indoor (virus sterilization), and there is no residue left in chemicals, etc.

- For determining the effectiveness of ultraviolet lamps and for determining the hardening of ultraviolet cured resin;

- Check UV sterilization process, check ultraviolet amount of sunlight

-

Condensation detection - Usage Example

- Assessing UV lamp effectiveness/Assessing hardening of UV-curable resin

- Confirmation of UV sterilization/Confirmation of sunlight UV level

-

Sterilization process monitoring card

-

Sterilization process monitoring card

-

FOR UV

5E 50 TEST

UV TEST

Temperature Indicating Materials – Usage Examples

For maintenance of electrical/electronic equipment

-

Power Transforming Equipment

- Monitoring abnormal temperatures in electric power equipment and terminal connections

- Line switch (LS) fixed contact exterior

- Oil circuit breaker (OCB) terminal fastener

- Transformer (Tr) terminal fastener and main body

- Silicon capacitor (SC) terminal fastener

- Monitoring abnormal temperature in current transformer (CT) terminal fasteners and super high-voltage transformers

-

Power Distribution Equipment

- Monitoring abnormal temperatures in busbars, circuit breakers and MBB connections inside power-receiving cubicles

- Pole-mounted transformer load management

- Monitoring abnormal temperatures in power capacitors, arc suppression resistors and terminals and blade parts of circuit breakers

-

Control Equipment

- Temperature monitoring of electromagnetic switches, electromagnetic contactors, electromagnetic relays, knife switches, high-voltage circuit breakers, high-voltage load break switches, power capacitors (parallel, high-voltage, series), surge arresters, inductive reactors, and magnetic amplifiers

-

Rotating Electrical Equipment

- Temperature monitoring of motors, Temperature monitoring of rotating machine parts

- Stator windings/insulated rotor windings

- Armature windings with commutators

- Resistive field winding and compensating winding

- Exposed single-phase field winding

- Commutators and slip rings

- Bearings

-

Electronic Components

- Circuit components: Temperature monitoring of capacitors, resistors, coils and integrated circuits

- Vibrating components: Temperature monitoring of crystal oscillators, mechanical filters and reed selectors

- Mechanical components: Temperature monitoring of electromagnetic relays, connectors, plugs, jacks and switches

- Semiconductor devices: Temperature monitoring of transistors, diodes, thyristors and integrated circuits

-

Power Transmission Equipment

- Monitoring for abnormal heat generation in jumper compression sockets and sleeves

- Temperature monitoring of terminals for feeder lines, negative feeder lines, overhead lines, support lines, feed branch connectors, jumper connectors, branch connectors, feed ears, connectors, and feeder switches

-

For monitoring household items

- Gas water heater water temperature sensing and burn prevention

- Temperature sensing for hot plates and frying pans

- Temperature sensing for hot sake bottles

- Monitoring/measurement of temperature inside refrigerators

- Room temperature monitoring/measurement

- Temperature sensing for electric moxibustion utensils

- Confirmation of body warmer ignition

- Temperature sensing for hair irons/hair curlers

- Temperature indication for vacuum cleaners with mite-removing function

-

For monitoring temperature in manufacturing processes

- 1. Mining

- Temperature monitoring of metal melting furnaces

- Determining completion of refining during electrorefining of copper

- Temperature monitoring for heat treatment

- Temperature monitoring of bucket conveyors

- 2. Automobiles/Shipbuilding

- Temperature monitoring during paint baking

- Confirmation of brake shoe adhesive hardening conditions

- Temperature monitoring of molds and dies

- Confirmation of engine internal temperature

- Confirmation of preheating temperature during welding

- 3. Electrical/Electronic/Communication Equipment

- Temperature monitoring during light bulb manufacturing

- Checking light bulb life

- Checking temperature increases inside electrical machinery

- Checking temperature increases of printed circuit boards

- Checking temperature in heat treatment for copiers

- Determination of heating factuality in response to complaints

- Temperature monitoring for heat treatment of heat-shrinkable tubes for communication cables

- 4. Food

- Level gauges for brewing tanks

- Checking temperature In heat processing during manufacturing

- Checking temperature in heat processing of udon noodle heating

- Confirmation of temperature during breadmaking

- Checking temperature rise during transportation

- 5. Textiles

- Temperature monitoring during printing

- 6. Schools

- Checking the temperature of sterilizing cabinets for school lunch utensils

- Checking heat transfer for educational materials

-

Combination temperature label A

-

Customized temperature label LI

-

Temperature label 3E

-

temperature label LI

-

Thermo paint

-

Thermosheet C

Temperature lable 3E -

UV label S

-

Combination temperature label TB

-

Temperature lable 3E

-

Sterilization process monitoring card

- Confirmation of processes for retort-packaged food/Checking completion of heating processes during canned food manufacturing

- Checking the temperature of utensil sterilizing cabinets for school lunches

- Confirmation of autoclave sterilization

-

Sterilization process monitoring card

- Temperature monitoring during transportation/storage of pharmaceuticals, chemicals and frozen food

- Temperature monitoring during low-temperature transportation

- Temperature monitoring inside warehouses

- Food freshness maintenance

- Checking temperature history during transportation of chocolate

- Checking the temperature inside refrigerators

-

FOR UV

- 1. Adhesion & curing

- For curing plates, such as camera modules, display panels, touch panels, etc.

- 2. Print

- Efficient drying hardening of ink such as paper surfaces, packages, sealabels, etc.

- 3. Painting & Coating

- Short construction time and excellent preservation performance for automotive parts, construction materials, and electronics

- 4. Washing, texture

- Effects of organic cladding, such as print substrate, condenser, silicon wafer, IC card, etc. or improve adhesion and adhesion. Utilize for high efficiency of processes

- 5. Sterilization

- It is used for accurate sterilization because there is little deterioration such as food, medicine, cleaning water, clean room, indoor (virus sterilization), and there is no residue left in chemicals, etc.

- For determining the effectiveness of ultraviolet lamps and for determining the hardening of ultraviolet cured resin;

- Check UV sterilization process, check ultraviolet amount of sunlight

-

Condensation detection - Usage Example

- Assessing UV lamp effectiveness/Assessing hardening of UV-curable resin

- Confirmation of UV sterilization/Confirmation of sunlight UV level

-

Sterilization process monitoring card

-

Sterilization process monitoring card

-

FOR UV

5E 50 TEST

UV TEST